Industrial Gas

A comprehensive equipment range for industrial gas uses across sectors

With a history spanning over 200 years and expert teams across the world, Fives offers a complete range of brazed aluminium heat exchangers (BAHX), centrifugal pumps, and reciprocating pumps for industrial gas uses.

The applications of our high-performance solutions range from steel and refining to electronics and healthcare. In addition to high-quality products, we offer clients support throughout the equipment lifecycle.

A high-performance pump for every application

Fives has more than 40 years of experience in the manufacture of pumps for all types of cryogenic fluids, with a centrifugal and reciprocating pump offer that meets the needs of a variety of industrial gas uses. This includes both distribution and process pumps.

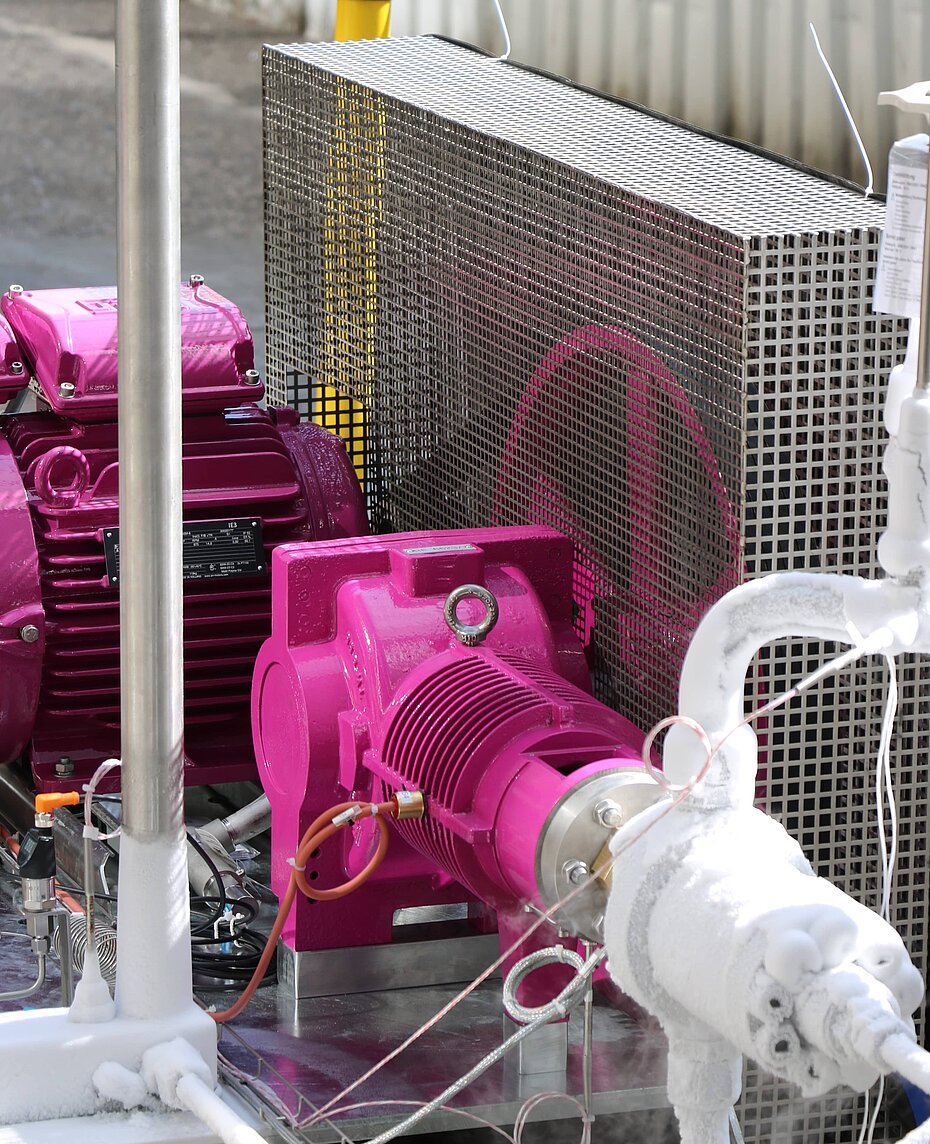

Our centrifugal pumps include the Cryomec® LABS (labyrinth seal), the Cryomec® NLL (mechanical seal), and the Cryomec® DGS (dry gas seal). These are designed for process and transfer applications, air separation units (ASUs), back-up units and truck loading pumps. They are also ideal as stationary pumps for liquid transfer, delivered as a turnkey solution with a skid and control box on request.

Our reciprocating pumps are the Cryomec® DELTA N, the Cryomec® LPRP / HPRP, Cryomec® THOR and the Cryomec® KPS. They are used in medical gases, intermittent or continuous duty, filling of cylinders, and liquid carbon dioxide and liquid nitrous oxide applications.

Fives’ Cryomec® pumps are designed to offer our clients increased productivity and a reduced total cost of ownership (TCO). We do not only focus on lowering the capital cost of our equipment, but also on reducing operating and maintenance costs. With this approach, we are able to achieve significant savings for our customers and for end users.

Reliable BAHX with exceptional mechanical properties

Fives is a pioneer and leading designer and manufacturer of the BAHX widely used in industrial gas applications.

Our expertise covers engineering, welding, quality control of new units, and reconditioning.

Our cutting-edge technology has been welcomed by the cryogenic industry thanks to its efficiency, compactness, and design flexibilities.

Our exchangers’ plate-fin structure enables the installation of a very large exchange surface area per volume.

This makes them ideal for certain gas/gas and gas/liquid heat exchange applications, where the temperature difference is small.

Due to aluminium’s mechanical features, our BAHX are perfect for the cryogenic processing of gases.

Examples of this include the production of industrial gases, and the processing of natural gas, liquefied natural gas (LNG), and helium.

Local and remote service for optimized maintenance

As a global company with a worldwide network of experts, Fives provides a comprehensive in-person service offer wherever clients are located. In addition, we offer remote services through an innovative smart glasses solution, which enables a representative at the customer site to be the eyes of a Fives expert located elsewhere. Any customer, anywhere in the world, can access our teams’ specific expertise.

We have also developed a digital solution to monitor installed BAHX and help our customers understand how they work. Called Fives Cryosens, the solution combines hardware, software, and Fives’ expertise to better asses the heat exchanger health during operation.